Transparent models

Transparent models Martina Felice3D printing and small series of transparent models

This guide is intended to help you understand how transparent models can be obtained from 3D printing and vacuum casting and, starting from the definition of the concept of transparency, provides indications on the possibilities and limits of these two solutions.

What is transparency?

When we say "transparent" we are all pretty sure of what we mean, but there are aspects of the concept of transparency that are worth investigating, to better understand what you can expect when you want to get a transparent prototype from 3D printing.

Transparency is the capability of a body to allow the passage of light and therefore the vision of objects located beyond it.

This capability is determined by two factors:

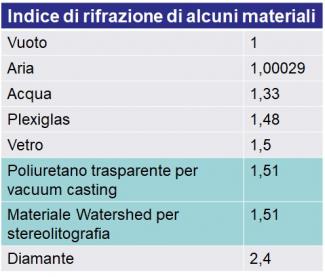

- by the material of which the object is made, i.e. by its index of refraction: for example, having conventionally set the index of refraction of the vacuum to 1, the air is indexed 1.00029, the water 1.33, the glass about 1.5, the diamond 2.4;

- by the surface of the object: if the surface is rough, the actual incidence angle of light is not what you see macroscopically but varies from point to point because the various light rays hit the microscopic facets of the roughness, each characterized by a normal, with an overall effect of reflection and diffusion or alteration of the path of the light rays, which reduces the actual transparency.

As a consequence, to obtain a transparent prototype it is necessary:

- to use a material with a good index of refraction, i.e. what we would call a transparent material;

- to have a surface as shiny as possible and free of macroscopic or microscopic geometric discontinuities.

How to get transparent models?

In the field of prototypes, the two ways to obtain this kind of result are stereolithography and vacuum casting.

In the case of stereolithography, it is necessary to use a transparent material such as Somos Watershed 11122XC and then proceed to finish the surface of the product until it is smooth and shiny. In most cases the object is then painted with transparent varnish to enhance the final effect.

The second path that can be followed to obtain a transparent model is to cast a transparent polyurethane inside a silicone mold. In this case, to ensure the transparency of the casted object, it is necessary that the master used to fabricate the mold, usually made by stereolithography, is perfectly polished and reflective, i.e. with the surface characteristics, and related problems, described in the previous paragraph.

Generally, it is worth following the first road when you want to make a single prototype and you want to contain costs, it makes sense to follow the second way if you want to make a small series of models and you are looking for more performing materials (in terms of mechanical strength and aesthetic quality).

Technical transparency or aesthetic transparency?

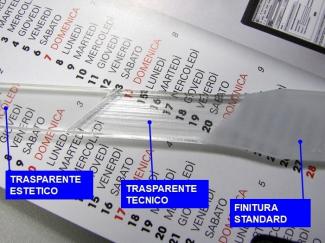

In both solutions described above, the methods required to polish the models involve a cost and, more importantly, they are not always possible. In general, in order to polish and paint an object, it is necessary that all its surfaces, internal and external, are accessible to finishing tools (usually manual tools) and to the paint that normally is airbrushed. If this is not possible, the transparency of the object will be somewhat reduced. This problem, however, is in many cases less restrictive than it may appear. To better understand the situation we should refer to the distinction that is made, in practice, between aesthetic transparency and technical transparency.

The aesthetic transparency is the "glass type appearance" that we can expect for example from a lamp or from a refrigerator showcase: a transparency that allows us not only to see through without any attenuation or deformation, but also to appreciate the smooth and glossy finish of the surface.

The technical transparency is instead what we can ask for a pipe fitting, where we want to see the liquid flow, or for a box that is designed to contain electronic parts: in this cases, it is important to see through the surface, but its aesthetic appearance is much less important because the defects are not relevant or are easily confused with the other elements that make up the assembly. In this case, even if you can not polish and paint all surfaces perfectly, often the final transparency effect is quite acceptable also because it is important to keep in mind that any geometric discontinuity (edges, ribs, holes, turrets, etc.) determines a reduction in transparency.

In conclusion, when you want to create a transparent prototype it is important to decide what the real needs are because the so-called "technical transparency", in not only easier and faster to obtain, but also less expensive.

For an easy consultation on other media, this guide is also available in PDF format:

Would you like to know more?

If you have any doubts about whether to choose the stereolithography solution instead of silicone molds, or you want to better understand if you need aesthetic or technical transparency, do not hesitate to contact us!