Selective Laser Sintering (SLS) is a technique that additively creates parts by sintering fine polymer powder particles, to fuse them together.

During the 3D printing process, the SLS machine preheats the bulk powder material in the powder bed just below its melting point, to make it easier for the laser to raise the temperature of the selected regions to the melting point.

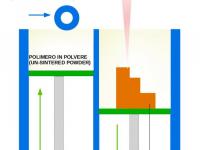

A roller applies a layer of polymer powder, then the laser sinters the powder according to the 3D file and the build platform gets down before applying a new layer of powder. Once it's finished, the plastic objects need to cool down before being extracted.

With SLS technology, many materials can be printed: plastic, metal, ceramics. The sintering of plastic usually uses nylon powder, possibly filled with fiberglass, aluminum, carbon fiber.

Advantages:

-

No support required

-

High heat and chemical resistance

-

High speed

Disadvantages:

-

Precision limited to powder particle size

-

Rough surface finish