Guide on the production of transparent models (3 of 3)

Just back from vacation, we complete our series of articles on transparent models. This guide, intended to help you understand how transparent models can be obtained from 3D printing and vacuum casting, is divided into three articles that deal with the following topics:

- What is transparency?

- How to get transparent models?

- Technical transparency or aesthetic transparency?

In the support area of the site is also available the guide on transparent models in complete and printable format.

Technical transparency or aesthetic transparency?

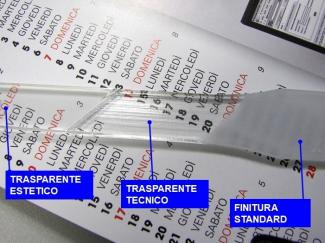

In both solutions described above, the methods required to polish the models involve a cost and, more importantly, they are not always possible. In general, in order to polish and paint an object, it is necessary that all its surfaces, internal and external, are accessible to finishing tools (usually manual tools) and to the paint that normally is airbrushed. If this is not possible, the transparency of the object will be somewhat reduced. This problem, however, is in many cases less restrictive than it may appear. To better understand the situation we should refer to the distinction that is made, in practice, between aesthetic transparency and technical transparency.

The aesthetic transparency is the "glass type appearance" that we can expect for example from a lamp or from a refrigerator showcase: a transparency that allows us not only to see through without any attenuation or deformation, but also to appreciate the smooth and glossy finish of the surface.

The technical transparency is instead what we can ask for a pipe fitting, where we want to see the liquid flow, or for a box that is designed to contain electronic parts: in this cases, it is important to see through the surface, but its aesthetic appearance is much less important because the defects are not relevant or are easily confused with the other elements that make up the assembly. In this case, even if you can not polish and paint all surfaces perfectly, often the final transparency effect is quite acceptable also because it is important to keep in mind that any geometric discontinuity (edges, ribs, holes, turrets, etc.) determines a reduction in transparency.

In conclusion, when you want to create a transparent prototype it is important to decide what the real needs are because the so-called "technical transparency", in not only easier and faster to obtain, but also less expensive.