Prototypes made in stereolithography can be finished in various ways, from basic finishing to RAL varnishing. Usually, the finishing is done only on the aesthetic side, unless otherwise agreed and with the exception of the transparent effect that requires finishing on both sides.

FB - Basic finishing

This type of finishing is the basic finish directly derived from the machine, without further processing, except those strictly necessary to separate the object from the support platform. Surface quality depends heavily on machine positioning that can highlight or hide process stratification.

FS - Standard finishing

This is the most common finish, consisting in sanding and sandblasting the piece, which thus assumes a translucent white appearance.

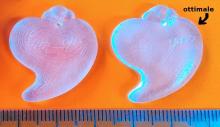

FT - Transparent finishing

With the Watershed 1122XC material, it is possible to obtain a transparent glass-like finish. This is possible by sanding, polishing and painting the workpiece on both sides, compatibly with the geometry of the part.

FM - Metal finishing

In this case, the prototype, after being polished, is subjected to vacuum metallization. The final surface is glossy and has a highly reflective power, but may have slight cracking, which may also occur over time, due to the different dilatations that characterize the resin and the metal.

FP - Painted finishing

This type of finish is obtained by painting the model with a color you choose, glossy or opaque (RAL or Pantone shades are possible). In this way you can also get opaque metal-like finishes.